This article will teach you everything you need to know about plywood, aka plywood! and answers all your questions. For example, what is the difference between multilayer types? Or what do you need to look for when buying a multilayer? Many woodworking projects require multiple layers. Wood product manufacturers are asked a lot of questions about plywood types. The usual answer: it depends!

The type of multilayer used in storage shelves is very different from the type used in children’s bookcases or kitchen cabinets. We hope this guide takes some of the mystery out of this versatile building material. In this article, we will teach you everything you need to know about plywood and other sheets!

Plywood is a composite material, which means that it consists of several layers glued together, the final output of which is a large sheet. It doesn’t matter what you build, a tree house or a real house. You will most likely need multiple layers.

When you glue many thin sheets of wood together so that the grain of each layer is perpendicular to the previous layer, the final product will be stronger and more flexible than when you use one piece of wood. Plus, it’s an easier and more economical way to cover large surfaces.

Usually, multi-layers are sold in dimensions of 122 x 244 cm. You may also be able to find smaller sizes called “panels” that are pre-cut to more manageable sizes.

First, the log is soaked in water, then it is placed in a large machine to be sliced - like peeling an apple. These sheets are called veneer or coating. The layers are glued together in opposite directions and pressed together to create plywood.

When I first started working with wood, I learned that the number of layers in a plywood determines the thickness of the sheet. I was confused when I realized that the 7th, 9th, 11th and 13th layer sheets could all be 19mm thick! More strangely, the thickness of most plywood boards is not 19 mm (or 12 or 6), but less! So it was natural that some of my projects didn’t turn out quite right!

So if you use multilayer in your work, why choose the more expensive 11-layer sheet instead of 7-layer sheet? Both have the same thickness, so their function and quality are also the same, right? No, it’s not!

The 11-layer plywood has thinner layers that are sandwiched between two layers of wood glue. Each of those wooden layers are less than 1.5 mm thick! More layers = more stability.

Note that the top and bottom layers of the 7-layer sheet are extremely thin, while the rest of the layers are thick enough. Now imagine sanding a 7 layer sheet. Your sanding will reach the next layer very easily! And this is awful!

The 11-layer sheet has more stable layers and the top and bottom layers are thicker. This makes it harder to sand the inner layers.

When you cut an 11-ply plywood, there is usually very little edge chipping because the wood glue holds the thinner layers together more tightly. In the case of cheaper 7-ply plywood, in large pieces the cut edge may break and weaken the bond between the two pieces.

Now, do you need expensive 11 ply baltic birch plywood for your first project? of course not! I will use only good stuff in the most beautiful furniture, which undoubtedly requires precision and quality.

The degree of multi-layering depends on the quality and appearance of the wood, especially the visible outer layers. The higher the grade, the more flawless the surface. Before choosing a multilayer, think about the end of the project and what you want.

Imagine you want to build a rock climbing wall. C/D grade cheap plywood is definitely a good choice. The texture of this wall is painted and covered with pebbles. There are some knots and holes in the outer layers, but for a rock climbing wall, that’s a plus!

For painted projects where both sides of the board are visible, such as a bench with the ability to store items under it for the entrance hall, grade B plywood can be used. The holes in the outer layers are covered and painted to cover any knots or imperfections for a flawless finish.

Grade A multilayer has a completely smooth surface and is suitable when you want to paint the work. There are no knots or flaws in it and both sides of the work are flawless. This is the most expensive type of laminate and is usually seen in high-end custom furniture or cabinets.

Sometimes, you will see two letters in the multi-layered grading. For example, A-B. That is, one side of the sheet is grade A and the other side is grade B. So one side will be completely smooth and the other side will have holes and patched knots.

This is useful. Because single A is more expensive than combined A and B. And on the other hand, it will not change your project. Because only one side of the work can be seen. For example, A-B multilayer can be used for drawer doors. Because one side is covered with wooden panels, while the other side is only painted.

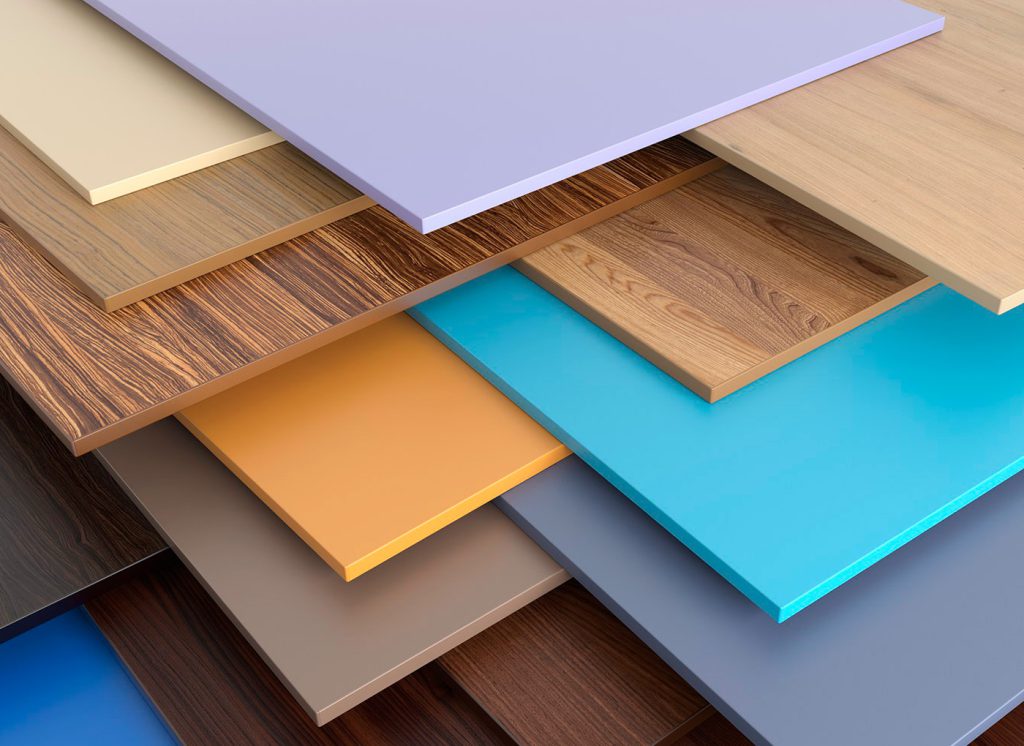

There are many different types of laminates and there are many to choose from. The main ones are listed below, but you can always use the recommendations of wood and timber products.

This type of multilayer is used for strong frames that you want to design on later. The main goal is to be as strong as possible. Construction multilayer exists only in two degrees C and D. It costs less than other options, but it takes a lot more work to make it look good.

In the wood industry, this type of multilayer is often used. Softwood plywood is usually less expensive and is made from Russian woods, pine, or spruce. It is more likely to bend and scratch, so it is not suitable for a tabletop. Hardwood plywood refers to the top layer wood such as maple or birch. Both types are found in grades A and D.

Exterior plywood is specifically made to withstand the elements. The glue used to hold the veneers together is water resistant. It also usually has more veneer layers than interior plywood. Therefore, there is more glue in the multilayer, which makes the sheet more resistant to water and mold. However, to protect the wood from rotting, you should use a waterproof finish such as exterior paint.

One of the best grades available is marine plywood. In each layer of veneer, all the holes are filled. The glue used is also waterproof so that the layers do not separate. This is why we recommend waterproof wood glue on all outdoor projects!

In addition to laminate, there are several other types of sheet goods that are commonly used. However, they are not nearly as strong as multilayers. These sheets are very durable in some conditions, but they cannot cover large gaps and bear a lot of weight.

MDF is one of the most common alternatives to plywood. It is made by mixing wood fibers and sawdust with glue and then pressing this paste in the form of a sheet. Sometimes the outer layer is covered with a thin layer of melamine, so in this case there is no need for finishing and painting after assembly.

The main advantage of this product is the perfect finished surface. Since it is completely handmade and synthetic, you don’t have to worry about any possible knots or defects in the product. However, because there is no wood grain, it becomes problematic if you want to paint your finished project.

MDF is very easy to cut and paint. However, it can’t withstand a lot of pressure, so if you don’t drill a smaller hole beforehand, for example, or if you don’t support the weight properly, the end product is likely to crack or crack.

Hardboard is very similar to MDF, but it is harder and thinner. It is made in the same way as MDF, but it is much more compact. It is usually used for the back of cabinets and bookcases.

Chipboard is the cheapest alternative to plywood. Because it is usually recycled material and is made from wood chips obtained from the waste of large plants and sawmills and wood mills and other wood products.

Chipboard is cheaper than plywood, but it is the least durable among all the mentioned products. This is the same material with which IKEA products are made and produced. It breaks easily and swells if it gets wet.

OSB is somewhat similar to chipboard, but made with large, thin chips and slices instead of small chips. Since its components are stronger, the board itself is stronger than chipboard.

OSB can be used for storage shelves, because they are not visible and do not need to look beautiful. OSB is an inexpensive option for covering a large area, but if you’re building something you’ll see all the time, I’d recommend the better material.

When you know the most suitable multilayer according to your needs, it’s time to buy the multilayer! Pay attention to several points when choosing wood.

1. The multilayer must be smooth. If it is warped, swollen or has waves in it, stay away from that product! These are signs of moisture damage or poor quality in general.

2. Be aware that sometimes there are two degrees of multilayer. Before you buy, look at both sides of the sheet so you don’t get surprised later.

3. Another thing that should be checked is clean edges without dents. If you get a piece of plywood with dirty and sloppy edges, it will be very difficult for you. Usually you place all the cuts on the factory cut edge, but if that edge breaks, your measurements are all messed up!