What is the difference between OSB and plywood? This article examines all the advantages, disadvantages and applications of OSB and multilayer, and in it an attempt has been made to provide a complete comparison of OSB and multilayer. Plywood and OSB are two of the most common sheet products that are used outside of Iran for house construction. The problem is that they look very similar and have a lot of overlap when it comes to end use. The problem is not only that they are very similar, but also that there is a lot of confusion about their differences and how and when each of them is used in construction projects. This handy guide will help you distinguish between plywood and OSB and choose the right type for your project!

Let’s start with an overview of the differences between OSB and plywood:

Price: Traditionally, OSB is the cheaper option, although prices vary based on your region and local market.

Efficiency: Both are relatively easy to use. However, plywood can be made into furniture and cabinets, while OSB is used exclusively in construction.

Coating: Almost both are interchangeable for use on ceilings, floors and walls. However, there is a hot debate about this, which we will discuss in some comments later.

Quality: Both OSB and plywood can be purchased with different qualities. Some are cleaner and more durable. Others are cheaper.

OSB stands for Oriented Strand Board. OSB is one of the synthetic building materials and is very similar to plywood, but they are not the same. OSB is made of wood shavings and chips that are pressed together with resin or glue under high pressure and heat.

Most people prefer to use OSB. Because there is no need to harvest large trees. OSB can be produced from small trees that are grown exclusively for this purpose, or waste and additions from wood cutting. There are different types of OSB in the world:

Standard OSB: used for roof, wall and floor. It does not have any special features, but you can get it in various sizes.

Zip OSB: This type of OSB is special for covering walls and ceilings in the outdoor space. OSB is zippered, waterproof. It is also pre-built and enables you to speed up your project.

Substrate OSB: Substrate OSB is smooth and strong. Many of its types have tongues and tabs on the edges that make it easy to connect.

In large projects, OSB is a cheaper alternative to plywood. However, OSB is not always the best choice for small projects. In construction projects, it is a suitable option for covering the roof, outer wall, sub-floor, because the multi-layer does not bend easily. Holds regular nails well, especially when nailed to joists under materials.

However, in smaller projects (such as building a box), the rough edges of OSB cuts do not make good corner joints. Because the screw or nail easily slides on both sides and your box will quickly fall apart!

Also, OSB does not have a wood veneer like plywood. The raw nature of OSB keeps prices down, but it’s naturally not visually pleasing! Even if you paint over it, you will still see the texture of wood shavings under the layers of paint.

However, this does not mean that OSB cannot be used for small projects such as warehouse shelves. When you just need a flat wooden panel that hides under the furniture, OSB helps to reduce costs!

Things to keep in mind when working with OSB:

OSB initially resists water because the resin and glue that holds it together repels moisture, albeit to a certain extent. Once saturated with water, it is very difficult to dry. OSB gradually bubbles and swells like a sponge, as a result of which the layers are separated and become unusable. Unfortunately, if your OSB expands, it will not return to its normal size when it dries.

OSB is more flexible than ordinary plywood. However, this does not mean that OSB is inherently weaker. It just means it could be a little more springy. For example, if you are using OSB in the subfloor, you want to make sure that the floor joists are not too far apart. Otherwise, you may end up with some bending in the floor. Of course, using a thicker OSB sheet will solve this problem. Also, use higher grade OSB.

OSB does not hold nails as well as plywood. For this reason, outside of Iran, the roof of wooden houses is usually made of ordinary plywood, because they feel that nailing is the best way to build a roof. Anyway, you have to test. Depending on the nails and type of OSB used, the results may vary. When in doubt, use screws.

OSB is water resistant, but not waterproof. The resin that holds the fibers and wood texture of OSB together is waterproof, but every cut edge exposes the interior wood to moisture. When these parts are exposed to water for a long time, they swell and begin to separate.

Using waterproof paint or putty on OSB helps prevent moisture penetration. You can also find exterior grade OSB that holds up better in the rain.

The strength depends on the thickness and quality of construction. However, overall OSB is stronger than MDF.

Conventional plywood is a good alternative to OSB. Although plywood is more expensive, it works at the same level as OSB.

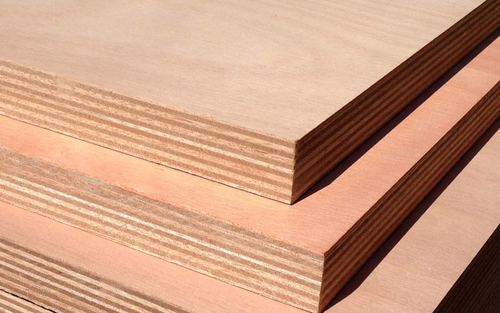

Plywood, which is also called plywood, is a sandwich of thin layers of wood pressed with glue in different directions of the grain of the wood. Multilayer has between 3 and 11 layers. Depending on the type of multilayer, one or more layers of hardwood are placed on the work, which we call veneer or layer or coating. You can buy veneered plywood that is produced in a wide variety of wood species. You can even get it painted to save you a step!

There are several types and degrees of multilayer:

highest degree. Smooth and sanded, no knots, and all voids filled. It is also called cabinet grade.

second degree Smooth and sanded, it may have defects up to 2.5 cm.

C grade multilayer: third grade. It has not been sanded and has more defects. The best option for back office use.

It is rougher than C, it has bigger defects. It is usually used instead of OSB for the substructure.

Also, you may see degrees like BC or CD. This rating indicates the superiority of one side over the other.

Where the surface is likely to be seen, use the better grade and hide the worse grade. When choosing a laminate, keep your project in mind. If it gets colored, use a worse grade multilayer. Because its defects are hidden.

Plywood is used as timber in all kinds of projects. Plywood not only works well for construction projects, but it is also useful for a wide variety of woodworking projects.

Multilayer is really versatile, but it’s not without its drawbacks. Below are some of the disadvantages of multilayers and how to fix them.

While plywood looks like solid wood, the edges tell a different story. Plywood layers are not visually appealing, especially if they are exposed along the edges of the holes.

Fortunately, there are a few ways to hide it! The easiest way is to use a wooden edge band. Edgebanding is a thin strip of wood on a roll with a ready-made thermal adhesive on the back. Just iron it on the laminated edge, then trim off the excess!

For a waterproof finish, cut thin strips of hardwood to the same thickness as the plywood, then glue and nail to the edge. Of course, in this case, a seam is created between the multilayer and the edge strip.

Finally, apply wood putty to the exposed edges and lightly sand when dry. This method is only recommended for painted furniture, but it’s better than leaving the edges raw!

Thin multilayer films are brittle and likely to become jagged after cutting. In this case, your project will look less professional. Of course, there are a few ways to prevent edge damage.

1. Use a sharp saw with many teeth.

2. Use a kenaf tip on the cut line to hold the wood fibers in place.

3. If you use a disc saw, cut the more beautiful side down, and if you use a table saw, cut the more beautiful side up. The blade should always be inserted from the better side so that any damage is behind the work.

4. Secure the bottom surface of the material with a sheet of foam insulation or a piece of scrap fiber.

Multilayer layering

When the multilayer is exposed to water, it dries relatively quickly and returns to its original size. However, repeated exposure to water leads to delamination or separation of layers. If your project is going to be constantly exposed to moisture, use a marine grade laminate to prevent this from happening. This product is made of special waterproof adhesives that keep the layers together in any weather condition. You can even use it to build a boat!

Nodes and empty spaces in multilayer

Some lower grades have multiple layers throughout the sheet, knots and voids. When the laminate is layered and pressed together, there are usually large knots in one layer. Sometimes, these nodes are lost and create empty space.

These empty spaces and nodes create defects in the project. To solve this problem, we recommend buying a high grade multilayer. Baltic birch plywood is free of voids and has a gold standard, which is known for its high quality in furniture making.

The price of multilayer depends on the market situation and the type of multilayer. In general, the thicker the sheet and the better the quality, the higher the price. Of course, construction grade plywood made from pine will be much cheaper than cabinet grade plywood made from birch.

The lifespan of the multilayer mostly depends on its quality and the amount of moisture it must tolerate. If you use the right laminate and protect it from water, it will last a long time.

It is not as beautiful as real wood and some types are expensive. Usually, cheap multilayer has knots and empty space, which can cause a decrease in the quality of your work.